When designing road cases for professional audio, lighting, and production equipment, one of the most critical decisions is the choice of plywood. The plywood core forms the structural backbone of the case, influencing its strength, moisture resistance, weight, and overall durability. At Armor Road Cases, we exclusively use WBP laminated birch plywood, a material selected for its superior performance in transport environments. In this article, we’ll explore the differences between commonly referenced plywood types—Standard, Marine, and WBP—and explain why WBP laminated birch is the optimal choice for road case construction.

Understanding Plywood Classifications

Plywood is often described using terms like “standard,” “marine,” and “WBP,” but these are not always formal categories. Instead, plywood is classified based on its core material, adhesive type, surface grade, and intended application. For example, “WBP” refers specifically to the adhesive used—Weather and Boil Proof glue—which is designed to resist delamination even after prolonged exposure to boiling water. This glue rating can be applied to various plywood types, including birch, tropical hardwood, or poplar.

Marine plywood, on the other hand, is a formally recognized grade under standards like BS 1088. It requires a void-free core and high-quality phenolic adhesives, making it suitable for environments where the material is in constant contact with water. Standard plywood is a general-purpose material typically used in furniture and interior construction, often made from softwood species and bonded with basic adhesives that are not moisture-resistant.

Why Standard Plywood Falls Short

Standard plywood is widely used in everyday construction and furniture-making due to its affordability and availability. However, its limitations become apparent when used in demanding environments like road cases. The adhesives used in standard plywood are typically not waterproof, making the material vulnerable to warping, delamination, and structural failure when exposed to humidity or rough handling. While it may be lightweight, it lacks the strength and resilience needed to protect valuable equipment during transport. For professional-grade road cases, standard plywood simply doesn’t offer the reliability required.

Marine Plywood: Built for Boats, Not Road Cases

Marine plywood is often considered the highest grade available, designed specifically for applications where the material is exposed to continuous moisture or even submersion. It features a void-free core and is bonded with waterproof phenolic adhesives, making it ideal for boat building and other maritime uses. However, road cases are not boats—they are not submerged in water or exposed to constant moisture. While marine plywood is certainly durable and water-resistant, it is overengineered for road case applications. It also tends to be more expensive and offers no significant weight advantage over WBP birch plywood. For these reasons, Armor Cases does not use marine plywood in our road case construction.

The Armor Cases Standard: WBP Laminated Birch Plywood

At Armor Road Cases, we use WBP laminated birch plywood because it offers the best balance of strength, moisture resistance, and practicality for transport environments. Birch is a dense hardwood known for its excellent structural integrity, making it ideal for cases that need to withstand frequent loading, vibration, and impact. The WBP adhesive ensures that the plywood resists delamination even under extreme conditions, such as exposure to humidity or temperature fluctuations.

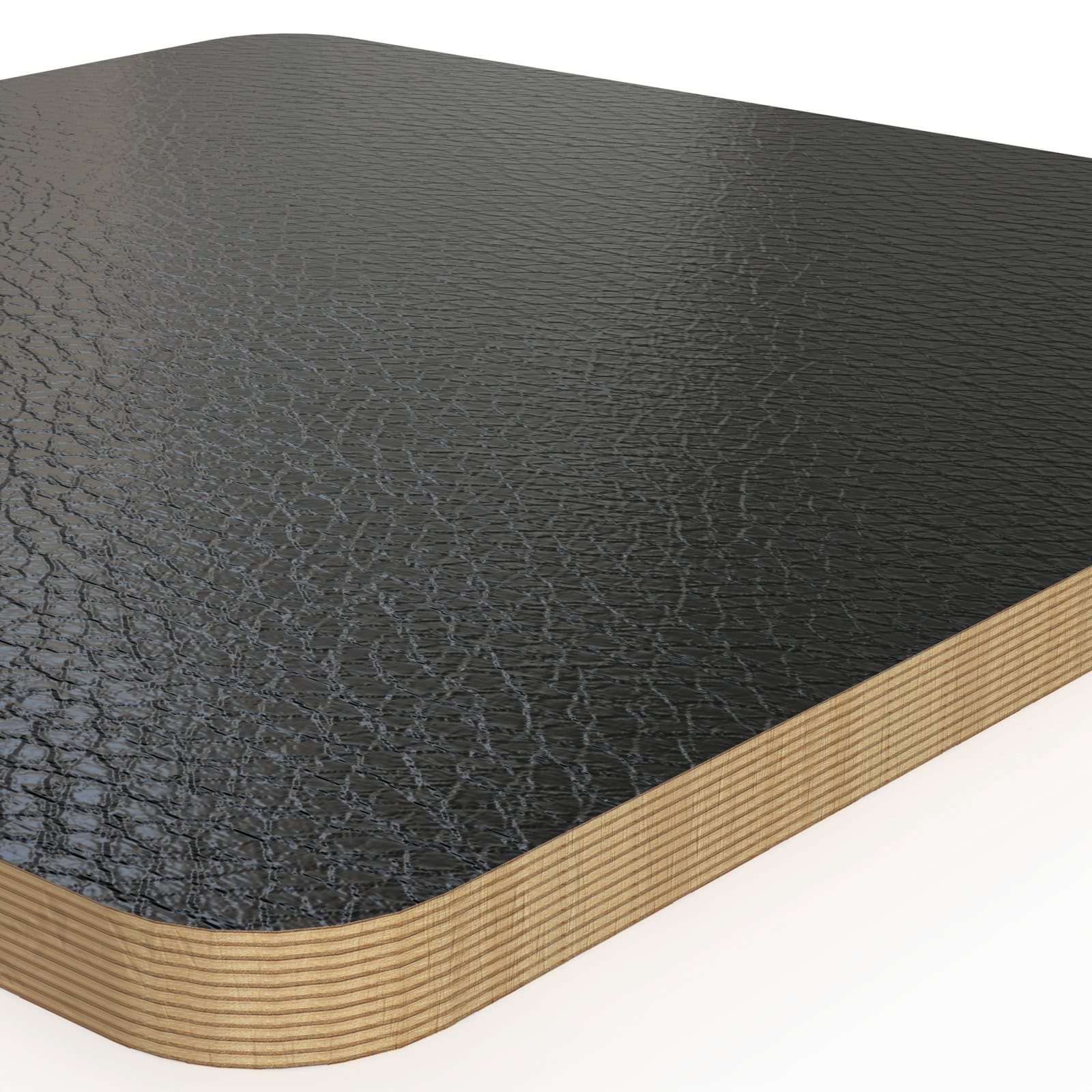

What sets our material apart is the laminated surface. Each sheet is coated on both sides with a high-pressure laminate (HPL), which adds a rugged, non-slip, and scratch-resistant finish. This not only enhances durability but also improves the case’s appearance and handling. While WBP birch plywood is heavier than standard softwood plywood, it is comparable in weight to marine plywood and offers superior performance for road case applications.

Standard plywood is the lightest, but its lack of moisture resistance and structural strength makes it unsuitable for protective transport cases. Marine plywood is strong and highly water-resistant, but its advantages are tailored to maritime environments. WBP laminated birch plywood, used by Armor Cases, offers the ideal combination of strength, moisture resistance, and durability without unnecessary weight or cost.

Why Material Choice Matters

Road cases are exposed to a wide range of challenges—from rough handling and vibration during transport to fluctuating temperatures and humidity levels. Inferior materials can lead to equipment damage, shortened case lifespan, and increased maintenance costs. By choosing WBP laminated birch plywood, Armor Cases ensures that every case delivers long-term durability and professional-grade protection. Our materials are engineered for the real-world conditions that touring professionals, production crews, and event companies face every day.

At Armor Road Cases, we build our cases with purpose-engineered materials that meet the highest standards of performance and reliability. Whether you're touring across Australia or managing a high-stakes production setup, our cases are designed to protect your gear and deliver peace of mind. Browse our road case panel category for details of the laminated plywood we stock.